OBJECTIVES AND HYPOTHESES

REPOWDER’s first aim is to develop new powders with improved performance resulting in printed parts with more uniform and predictive properties, less residual stress and lower susceptibility to cracking than the existing ones. Focus will be on optimizing powder specifications; including chemical composition of one of the most commonly used materials: stainless steel, type 316L. REPOWDER’s second main aim is to quantify available stainless steel scrap resources and establish how they can best be made available for AM, including modifying and optimizing their composition. We will use this information to classify available scrap with regard to quality and quantity and document that high quality powders can be made from recycled steel.

Our hypotheses are:

- We can significantly improve the quality of AM parts by tailoring the powder to the process.

- There exist stainless steel scrap resources that, if made available, can significantly reduce the environmental impact and price of AM products.

The success criteria are:

- A new stainless steel powder designed to encompass the fast heating and cooling rates of AM,

providing the optimal phase composition and microstructure after printing.

- Complete life cycle analysis of upcycling stainless steel scrap from high-quality scrap from

component production and lower quality, end-of-life scrap from used components.

- A break-through in the scientific understanding of the relationship between microstructure and

properties in AM samples as a function of powder quality.

- A unique research infrastructure for developing customised powders accessible for the Danish AM community.

- A guide to optimizing powder composition for AM using stainless steel scrap as feedstock.

RESEARCH PLAN

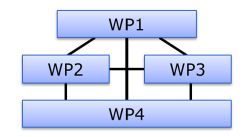

The project is divided into 4 scientific, closely related work packages (WPs), as sketched in Fig 2,

and 1 management WP, each having different milestones (MSs):

Figure 2: Flowchart illustration of how the scientific work packages interact.

WP1 Establishing research facilities for powders (Leader Niels S. Tiedje DTU)

WP2 Environmental System Analysis (Leader Henrik Wenzel SDU)

WP3 Alloy design (Leader Niels S. Tiedje DTU)

WP4 3D printing and post processing – characterization of microstructures and properties (Leader Tianbo Yu DTU)

WP5 Management and safety (Leader Dorte Juul Jensen DTU)